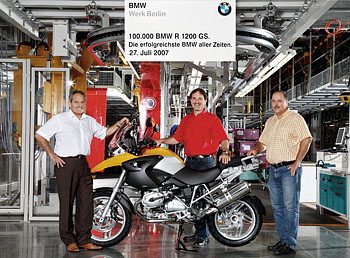

The 100,000th BMW R 1200 GS Dual Sport!

On This Page:

The BMW R 1200 GS, together with the model variant Adventure, celebrated an impressive record.

In Berlin, the 100,000th 1200 GS rolled off the assembly line!

84,373 units of these were allotted to the classical GS, and 15,627 units were allotted to the model Adventure.

No other BMW motorcycle has ever been built so often within such as short space of time. Hence, the BMW R 1200 GS is the most successful BMW motorcycle of all times.

The predecessor has held first place of the registration statistics for years; the 1200 GS already managed to achieve this right from the start.

It has continued extending its lead to this day. In 2006, 31,138 units were delivered to customers worldwide.

From 1999 until 2003, the predecessor model R 1150 GS was built a total of 58,023 times. In addition to this, 17,828 units of the model variant Adventure (until 2005) were produced.

Since 1994 to this day, a total of 219,468 GS models of the boxer engine generation with four valves per cylinder have been built. A figure that proves the popularity, supremacy and unique universality of the GS concept.

Significant New Improvements To The Most Popular BMW Motorcycle

The BMW R1200GS was named Motorcycle of the Year! The BMW R1200 GS also won the IDSA 2004 Industrial Design Excellence Competition in Los Angeles, California on June 25, 2004.

“Once again, BMW Group has sped past the competition, winning Gold in the Industrial Design Society of America’s 2004 IDEA (International Design Excellence Awards) for the R1200 GS BMW Motorcycle.

This marks a stellar repeat performance for BMW Group’s Design Team.

Last year, the BMW Group received several awards from the Industrial Design Society of America (IDSA), including Gold awards for MINI, Gold and Bronze awards for DesignworksUSA and a Bronze for BMW Motorcycles.”

BMW Increases Production of R1200GS

Due to the enormous demand, BMW Motorrad has decided to increase the production of the R 1200 GS.

“Incoming orders have exceeded all our expectations and we want to reduce delivery times for our customers as fast as possible. The aim is for customers who order now to receive their motorbike in the summer”, says Peter Müller, head of sales and marketing of BMW Motorrad.

Additional shifts have been arranged in the short term with the work force of the Berlin motorcycle plant. All suppliers are also co-operating.

“This shows”, says Dieter Schliek, plant director in Berlin, “how very flexible our workforce is and how it is dedicated to satisfying our worldwide customers.

Quite a few employees were even willing to put off their annual holiday so that the R 1200 GS could also be assembled during the plant holidays.”

BMW Press Release

The new BMW R 1200 GS fulfills the old dream of the ideal touring enduro: Superiority in every respect and outstanding performance and superior comfort even on the longest tour.

Also, equally superior handling and agility for maximum riding pleasure on winding country roads and mountain passes give the rider exactly what he wants.

Add to this the low weight of just 225 kg or 496 lbs., which is quite unique in this class, plus outstanding chassis and spring qualities, and you can be sure to enjoy even the toughest tours on the roughest terrain.

The BMW R 1200 GS offers an unparalleled synthesis of harmony in its combination of off-road an on-road riding qualities.

Its predecessor the R 1150 GS was uniquely successful over so many years; it set the standard in its segment consistently throughout its lifecycle.

Now the R 1200 GS now takes you into a new dimension, raising the outstanding features of its predecessor to an even higher level on all important counts.

Summary of R1200GS Specifications: (top)

- Weight reduction of 66 lbs. through precise calculation, intelligent lightweight construction, and the use of high-strength materials.

- New 1200-cc Boxer-twin power unit with balance shaft for supreme smoothness.

- Torque and output increased by 18 percent.

- Fuel consumption reduced by 8 percent.

- Sodium filled exhaust valves.

- Highly advanced, newly developed engine electronics using CAN-bus technology (Controller Area Network) and the latest emission technology for optimum environmental compatibility.

- Quiet exhaust system with a throaty sound.

- All-new six-speed gearbox with superior running smoothness and shift

comfort. - Newly-developed lightweight Paralever with weight-optimized driveshaft.

- New Telelever for even greater precision in front wheel guidance plus low

weight. - All-new, extra-stiff running gear for greater safety, outstanding directional

stability, superior handling and accuracy in turns. - High-performance EVO brakes with on-demand Integral ABS.

- High-strength cast light-alloy wheels and cross-spoke wheels available as

an option. - Electronics used for fewer cables and lower weight.

- Electronic immobilizer standard.

- Wide range of equipment and tailor-made accessories to BMW’s high

standard.

BMW R1200GS Press Release

BMW R1200GS Press Release

At the same time it goes without saying that the R 1200 GS continues all the traditional features and fortes so characteristic of all BMW motorcycles.

First-class and extra-safe riding conditions ensured by even more stable running gear with the unique BMW Telelever for the front wheel and a newly designed weight- and geometry-optimized Paralever at the rear.

High-performance brakes of the highest caliber together with BMW’s unique Motorcycle Integral ABS guarantee supreme safety even in a critical situation.

Superior environmental compatibility, in turn, is ensured by a fully controlled three-way catalytic converter with the most advanced emission management – a technology, incidentally, which has been a natural feature on all BMW motorcycles for years.

It’s equipped with dual ignition and a brand-new Digital Motor Electronics featuring integrated knock control.

Also, a further improved catalytic converters and separate oxygen sensors for each cylinder.

The R 1200 GS increases the leadership of BMW motorcycles in the large-volume touring enduro segment to an even higher standard than ever before.

A further feature not to be forgotten is the maintenance-free driveshaft avoiding the need for unpleasant and time-consuming service particularly on long trips.

The sophisticated new luggage system and the wide range of accessories available straight from the factory and tailored to the R 1200 GS also help to clearly prove that this new machine is powerfully continuing the tradition of large-capacity BMW touring enduros.

That tradition goes back almost 25 years to the R 80 G/S launched in 1980: This is most certainly the original straight from the inventor of this type of motorcycle, a machine once again setting the standard in this class

Technical Details of the R1200GS (top)

In its design principle and fundamental structure, the newly developed flat-twin power unit of the R 1200 GS follows the same standards as BMW’s former, proven engine.

But at the same time the new power unit is a new development all-round, with fully revised and improved components.

Optimization of engine geometry and application of the most advanced calculation and simulation methods serve to reduce the weight of the engine by 8 percent despite its larger capacity and wider range of functions.

Engine width, in turn, is the same as before.

This is the biggest engine ever seen in an enduro so far, the increase in capacity to 1,200 cc, providing the foundation for superior output of 100 bhp and muscular torque throughout a speed range wider than ever before in the past.

The result is superior power under all conditions and in all situations – clearly a great advantage above all on difficult off-road terrain, with power and torque constantly available regardless of engine speed, the gear in mesh, and the conditions facing the rider.

Balance Shaft

Balance Shaft

The most important innovation featured on the basic engine block is the balance shaft eliminating any unpleasant vibrations.

Despite their superior design principle with the cylinders opposing each other to provide a perfect balance of primary forces (connecting rods and pistons moving to and fro) in their overall effect, conventional flat-twin engines cannot run entirely without vibrations.

The inevitable displacement of the cylinders always generates “circulating”, or secondary forces (that is forces not acting on one and the same level) causing unpleasant vibration the rider will feel on the handlebar, footrests and seat.

The severity of such mass forces and the vibrations caused in this way increases as a function of engine size and, in particular, engine speed.

Precisely this is why the engine of the R 1200 GS is the first power unit in the history of the Boxer engine to feature a balance shaft.

Running in the opposite direction, the shaft carries two balance weights 180 degrees apart from one another and exactly spaced out in size to provide a counter-force which, superimposed on the mass forces in the crankshaft, reduces vibrations to an absolute minimum.

This keeps running conditions smooth and comfortable throughout the entire speed range, vibrations even being dampened in particular at low engine speeds without the flat-twin losing its bullish character.

The balance shaft itself is arranged exactly where it should be, saving space through its intelligent and elegant concept.

Running in anti-friction bearings, the balance shaft is positioned within the countershaft and is driven by a spur gear from the crankshaft (direct 1:1 ratio).

The rear balance weight is outside of the oil cavity and is bolted on to the shaft extending completely from one end to the other. The front balance weight, in turn, is integrated in the drive sprocket.

Like on the former engine, the countershaft again serves to drive the oil pumps and carries the sprockets driving the camshaft.

The transmission ratio of the countershaft versus the crankshaft is therefore 2:1, the countershaft itself being driven by a roller chain.

The crankshaft is also a new design from the ground up – it is now even more compact in the interest of extra stiffness and the crankpins themselves are even closer together (a modification made possible by the narrower counterweights).

Despite the increase in stroke from 70.5 mm or 2.78″ to 73 mm or 2.87″, this change in design helps reduce weight by 1 kg or approximately 9 percent.

And to give the rotating assembly the balance effect required, some of the counterweight masses have been moved to the flywheel and the drive gear on the balance shaft.

As before, the flywheel holds the single-plate dry clutch enlarged in diameter from 165 to 180 millimeters (6.50–7.09″).

The clutch lining is free of asbestos and heavy metals, the pressure plate, membrane spring and gear plate being balanced individually to allow easy and convenient assembly of these components without any negative effects on running smoothness.

The piston design has been slightly revised and features three rings. Weighing just 410 grams they are a bit lighter than the former R 1150 GS’s pistons (420 grams).

Through the use of advanced casting and computer technology, the crankcase is a lot lighter than before. It has been optimized in wall thickness as well as stiffness and strength. Weight has also been reduced in the process by 1.4 kg (3.1 lbs.).

Well-conceived and effective solutions are also to be found in the details of the engine design.

To minimize undesirable pressure pulses within the crankcase, (the air pressure going up and down as a result of piston motion), a small valve assembly opens and closes the air purge outlet automatically as a function of pressure conditions in the crankcase cavity.

And at the same time, provides a large air purge cross-section whenever required.

This serves to reduce pressure fluctuations and air flow in the crankcase to a minimum, with an advantageous effect on engine output, internal efficiency (reduction of ventilation loss), oil foaming, and oil consumption, particularly at high speeds.

New Cylinder Head Design

Maintaining their basic design and configuration, the cylinder heads have also been modified; from outside they are recognizable by their different shape and less-rounded rocker arm covers.

The principle of chain-driven camshafts below the valve plane and the operation of valves by means of tappets and rocker arms has been maintained.

The reason, quite simply, is that this design concept has proven its qualities countless times.

And although it is not necessarily designed and laid out for high speeds, the concept has confirmed its qualities and reliable function even under tough racing conditions in the BMW Motorrad Boxer Cup.

The big advantages of arranging the camshafts in this way are the economic use of space available (width of the cylinder head) and the ease of maintenance so important both in everyday use and on long journeys (adjustment of valve clearance).

Valve face diameters have increased by 2 mm (0.79″) on the intake and exhaust valves to 36.35 mm/1.43″ and 31.0 mm/1.22″, respectively.

To ensure better and more efficient dissipation of heat, the exhaust valves are filled with sodium. Valve duct design has been modified to match the larger valve diameters and the duct contours have been improved in their dynamic flow conditions.

In conjunction with the increase in engine capacity, these modifications contribute to the 18 percent increase in engine output (100 hp) and torque (85 lb-ft).

As the final result of this design improvement using the most advanced, computer-aided methods, weight of the cylinder heads has been reduced by 15 percent.

Internal oil cooling of the cylinder heads already featured on the former engine has been adjusted to the higher level of output and torque by improving flow conditions and avoiding any kind of throttle effect.

Oil cooling improves the dissipation of heat from the valve rim and ensures a more consistent distribution of temperature within the cylinder head.

All this contributes to the engine’s robust thermal stability and helps to ensure the high standard of reliability so typical of a BMW. And these are definitely the criteria that count when traveling full of luggage to all four corners of the globe under the most difficult conditions.

New Engine Management Systems

Engine management now features two oxygen sensors, modified dual ignition and knock control.

The new R 1200 GS further improves the leading position BMW Motorrad has had for years in the area of electronic engine management.

The Digital Motor Electronics code -named BMS-K (BMW Engine Management System) is an in-house development tailored specifically to the requirements of a motorcycle.

Fully sequential fuel injection, integrated knock control, faster processing of complex sensor signals by means of the most advanced microelectronics, compact layout and low weight are the most important features worth mentioning in this context.

The principle of indirect air volume monitoring and control by means of the throttle butterfly angle and engine speed (alpha-n control) carried over from BMW’s existing motorcycles has been further enhanced on the R 1200 GS.

This creates a concept referred to as torque-based engine management.

The basic parameters determining the optimum engine operation point remain engine speed and the throttle butterfly angle monitored by a separate potentiometer on each cylinder.

Applying additional engine and ambient parameters (such as engine temperature, air temperature, and air pressure), engine management, together with control maps and correction functions contained within the system.

It tailors the injection volume and ignition timing exactly to the engine’s and rider’s current requirements.

Taking these many factors into account, the system is able to control torque with supreme accuracy, adjusting engine running conditions perfectly to all relevant parameters.

Fuel is injected into the intake duct exactly as required and exactly on time for the intake cycle of each cylinder (fully sequential fuel injection).

With one oxygen sensor being allocated to each cylinder, fuel/air composition is controlled individually in each cylinder according to current requirements.

Both oxygen sensors are arranged close to the engine in the respective exhaust manifold, thus ensuring individual and even more precise emission

management.

Whenever necessary, the fuel/air mixture may be adjusted much faster than before, naturally with individual control and adjustment of each cylinder.

The positive results of this process are exemplary emission management, greater fuel economy, improved riding conditions, and an even finer response to the rider’s commands.

Or, to put it in a nutshell, even greater environmental compatibility together with enhanced sheer riding pleasure.

BMS-K also incorporates all the functions of automatic idle speed control as well as cold start enrichment with warm-up control.

An appropriate increase in idle speed while warming up is ensured automatically by so idle speed steppers integrated in the throttle butterfly manifolds, together with a corresponding adjustment of the fuel injected.

Featured in all BMW Boxers (with the exception of the 850-cc power units) since 2003, Twin Spark ignition has been further modified and improved in the R 1200 GS.

The auxiliary spark plug is now arranged at the outer edge of the cylinder, the ignition timing of both plugs being freely programmable and possibly varying in time as a function of load and engine speed in order to further optimize running smoothness, emission management, and fuel economy.

Referred to as phase shift, this adjustment process is maintained consistently all the way from part load to full load.

In practice, this means different ignition timing points on both spark plugs in defined control map areas.

When approaching full load where dual ignition no longer provides any benefits, the phase shift effect is so large that the spark crosses over on the auxiliary plug in the expansion cycle (60 degrees ATDC).

For all practical purposes, this corresponds to single ignition on the central spark plug under full load.

The BMW R 1200 GS introduces a new system of knock control never seen before with these features in a motorcycle engine. Engine knock is recognized by a solid body sound sensor matched specifically to the cylinders.

Receiving the appropriate signals, the electronic engine management will retard the ignition and protect the engine from possible damage.

Engine temperatures are also taken into account in evaluating the signals, helping to supplement the safety function.

Benefiting from knock control, the mechanical combustion ratio on the engine has been increased to 11.0:1, certainly a remarkable figure for an air/oil-cooled engine with cylinders of this size.

Specific fuel consumption benefits accordingly, the R 1200 GS being almost 8 percent more fuel-efficient than its predecessor in the EU2 test cycle.

Designed for unleaded premium fuel, the engine, thanks to knock control, is able to run also on regular fuel or other fuel qualities sometimes to be found in various countries, without requiring any kind of manual intervention or adjustment.

Within the limits available, knock control adjusts the ignition angle automatically to the fuel on which the engine is running.

Interacting with a wide range of sensors, knock control adjusts to even the most extreme conditions and requirements, for example with the engine having to withstand extremely high temperatures and thermal exposure in desert areas.

To provide this reliability, the electronic engine management adjusts engine running parameters and thus ensures supreme reliability under all conceivable operating conditions.

New Intake Manifold Design

Intake manifold now has larger volume for an optimum cylinder charge.

Numerous calculations and examinations of the entire cylinder charge process, taking the intake manifold into account, were required in order to achieve an optimum charge cycle throughout a wide range of engine speed.

Increasing the capacity of the airbox to almost 9 liters, BMW’s engineers have made the very best out of the conditions dictated by the machine and the specific position of the manifold, naturally taking all ergonomic requirements into account.

To filter the intake air, the R 1200 GS uses the paper filter system already very effective in the R 1150 GS.

In designing and configuring the shape of the intake funnel, the responsible engineers have succeeded in creating perfect harmony of flow conditions and acoustic requirements (level of intake noise).

Revised Exhaust System

The new exhaust system has efficient sound engineering for low noise with a throaty note. The exhaust system is made up of two manifolds, a pre-silencer with catalytic converter, and a tailpipe muffler.

The entire system all the way to the pre -silencer fitted beneath the gearbox is a twin-chamber configuration made consistently of stainless steel. Weighing exactly 10.7 kg or 23.6 lbs. overall, the emission system is approximately 33 percent lighter than on the former model.

Flowing through the two single manifolds, exhaust gases merge in a Y-shaped unit combining the two flow processes and continue into the pre -silencer that houses the central catalytic converter.

A crossover tube between the two manifolds provides the appropriate balance of pressure and helps boost engine torque at low and medium speeds.

With cell density of 200 cells per square inch, the metal-based catalytic converter comes with a rhodium/palladium coating combining high temperature resistance with a long service life.

Introducing an all-new tailpipe muffler, BMW Motorrad has succeeded in creating an ideal match of smooth torque, low noise and a pleasant sound pattern.

The interior structure of the muffler is based on the reflection principle, an inner sleeve with absorption material serving additionally to dampen high frequencies.

The muffler is oval in shape not only for aesthetic reasons, but also to minimize the transmission of noise for smoother and more pleasant riding conditions.

Another special feature is the pressure -controlled valve integrated in the muffler and controlling exhaust gas counter-pressure for an additional reduction of noise under the engine’s primary running conditions.

That is at medium-to-low engine speeds, thus keeping engine noise at a low level both objectively and subjectively, while at the same time giving the rider that “throaty” sound that he – or she – appreciates so much.

Lightweight Alternator and Starter

Both alternator and starter lighter than before. Apart from the mechanical components in the engine, the electrical ancillary units also help to reduce weight to a minimum.

To begin with, the R 1200 GS features a newly developed lightweight alternator with maximum power of 600 Watts.

The layshaft starter has also been optimized for lower weight, and just like the battery, it is absolutely free of maintenance requirements. In all, the total weight saving on the electronic components is 2.2 kg or 4.9 lbs., which is 17 percent lighter than before.

New Six-Speed Manual Gearbox

Now with helical gears. The R 1200 GS retains the proven principle of separating the gearbox from the engine.

And at the same time the six-speed manual gearbox is an all-new development with features significantly improved once again over the previous version.

Weight has been reduced to approximately 13 kg or 28.7 lbs. and for the first time, BMW is using high -strength helical gears with smoother and more gentle gear mesh to ensure low noise and a high standard of refinement.

All gear increments are designed for active riding behavior, meaning that sixth gear is not an overdrive or economy gear, but rather has an appropriately “short” transmission ratio.

The gear shafts run in anti-friction ball bearings, the gears themselves in low-friction needle bearings. The ball bearings come in clean bearing mounts sealed at the surface to keep out even the finest particles.

This allows even longer maintenance intervals and reduces the cost of service, with only one oil change required in the gearbox every 40,000 km or 25,000 miles.

The gears themselves are shifted by means of a shift roller, shift forks and shift sleeves (as opposed to shift gears used in the past) to ensure smooth positive engagement of the gears.

Made of aluminum, the hollow shift roller runs on ball bearings.

Detailed improvements to optimize friction on the shift box, the shift shaft and forks improves gearshift operation once again and guarantees accurate, safe mesh on all gears.

Revised Lightweight Shaft Drive and Paralever

An absolutely indispensable feature of the new R 1200 GS like on all BMW Boxers is the traditional, maintenance -free shaft drive extending to the rear wheel.

Having proven its merits for more than 80 years, this is the only logical drive concept with the crankshaft in longitudinal arrangement.

And in practice, this concept reaps great benefits for the customer, considering that chain drive, despite many improvements over the years, is not quite appropriate given the need to regularly tighten the chain and the short lubrication intervals, for a large -capacity, high-power touring enduro.

Over the years, BMW has consistently improved the shaft drive principle, meeting new requirements and demands in the process.

The biggest innovation came in 1988 with the introduction of the Paralever swinging arm on the most powerful enduro at the time, the BMW R 100 GS.

By using an additional pivot between the final drive and the swinging arm, BMW’s engineers were able to nearly eliminate the unavoidable reaction of the driveshaft from the swinging arm.

This eliminated the “shaft effect” with the rear end moving up and down when accelerating and applying the brakes.

A further advantage provided by the Paralever is that the springs do not harden when accelerating all-out, providing a significant improvement of traction as an important feature when driving up steep gradients on very rough terrain.

Considering these significant benefits, the higher weight and the increase in unsprung masses with a driveshaft versus chain drive are insignificant.

In developing the R 1200 GS, BMW’s engineers did not stop until this feature of the system was optimized on this enduro motorcycle that is used more often off-road than on.

The result is a drivetrain that together with the much stiffer Paralever swinging arm, reduces weight by approximately 10 percent.

Unsprung Weight Reductions

Unsprung masses are down accordingly, ensuring an even more sensitive response than before on the rear wheel suspension already acknowledged for it superior qualities.

The main components of this new system are the axle drive and the swinging arm itself. Made of an ultra-strong cast aluminum alloy, the Paralever swinging arm, through its design and specific dimensions tailored to load conditions, is even lighter than before but also stiffer and stronger.

The geometric configuration of the entire swinging arm has likewise been modified, dive compensation is now almost 100 percent.

With forces acting on the final drive housing now being supported above the swinging arm, ground clearance at this point is greater than before, efficiently protecting the swinging arm even on very rough terrain against damage caused by rocks or similar objects.

The swinging arm itself is a two -piece forged aluminum unit. Another new feature is the reconfiguration of the swinging arm mount moved from the final drive to the rear frame again in the interest of extra strength under the most extreme off-road conditions.

The pivot point of the axle drive unit resting in the swinging arm has been moved down to provide a more favorable geometric arrangement with greater stiffness.

The bearing point, in turn, has been reinforced to match the higher load and forces from the more powerful engine.

Drive Shaft

With its improved kinematics, the driveshaft no longer changes in length as a result of geometric conditions. This also helps to save weight, since the plunging joint unit is no longer required.

The shaft itself now comes as one single piece and – like before – runs without oil in the shaft sleeve.

The final drive housing is matched in its size and dimensions precisely to the inner contours of the angle transmission, avoiding even the slightest waste of space.

The hub assembly has been redesigned and is also lighter than before. The wheel flange is now being made of aluminum in order to save weight.

With its larger diameter, the flange offers the wheel better support, with additional weight-saving potentials for the rear wheel around the hub.

The outer sign of distinction and a visual highlight of this extremely compact and elegant lightweight structure is the 50-mm hole drilled through the axle of the final drive housing.

The final drive itself comes with a lifetime oil fill, meaning that there is no need to change the final drive fluid throughout the entire running life of the motorcycle.

In re-configuring the design principles of the entire machine, assembly of the final drive has been simplified and further refinements introduced.

The hollow axle sleeve helps to dissipate heat from the final drive through its large surface and efficient flow effects.

ABS Brakes

Signals for the ABS brake system and the speedometer are read by a sensor mounted directly on the Paralever arm, making the outer emitter wheel used on the former model superfluous on the new machine.

Increasing the diameter of the drill holes on the wheel flange, BMW’s engineers are able to use five light wheel bolts measuring 10 mm in diameter and with longer expansion length instead of the former relatively heavy wheel bolts with a cone.

This means even greater safety once again in bolting on the wheels and allows use of a smaller wheel bolt wrench (which means less weight in the toolkit).

New Running Gear

Now with stiff, high-strength steel tube frame. The R 1200 GS retains the basic configuration of all Boxer suspension concepts with the engine/transmission unit serving as a load-bearing element and the wheel guidance components being bolted on to the frame.

The Telelever longitudinal arm, in turn, pivots on the engine housing, as before.

The actual frame of the R 1200 GS is made up of the front sub-frame supporting the Telelever at the top and the rear frame with its integrated swinging arm mount. The engine/gearbox unit is bolted on to the rear frame at four and on to the front frame at two points.

Together, this composite structure incorporating the drive unit forms the motorcycle’s load-bearing framework.

The two frame elements of the R 1200 GS are lightweight structures in what is called truss design: The front frame is a triangular structure made up of high-strength steel tubes welded to one another.

It offers the great advantage of highly robust support on off-road terrain plus package benefits over the former cast aluminum front frame as well as greater stiffness with weight remaining unchanged.

The rear subframe is also made up of straight steel tubes welded to one another.

Precise calculation of all tubes serves to optimize both tube diameter and wall strength to exactly the right requirements, creating an overall configuration of maximum stiffness and strength on low weight.

New features are the special mounts for the side-stand and main stand as well as the driver’s footrests connected directly to the rear sub-frame.

The side -stand, incidentally, folds in easily and conveniently even when the rider is already sitting on his machine.

Refined Telelever

To this day, no other system of front wheel guidance and support is able to match the first-class functions and qualities of the BMW Telelever introduced in 1993 on the four-valve Boxers.

The revolutionary principle of the Telelever using a wishbone to relieve the telescopic arm of longitudinal and lateral forces ensures unprecedented, highly sensitive front-wheel response on all road surfaces, together with tracking stability never seen before.

The big advantages of this design concept are supreme riding precision and response combined with the utmost in suspension comfort and anti-dive control.

Refinement and modification of the front wheel geometry now further improves the qualities of the Telelever on the R 1200 GS over the former model.

The longitudinal arm is an all-new, extra-strong and light forged aluminum component.

In the interest of superior handling, front wheel trail has been reduced by 5 mm (0.20″) to 110 mm (4.33″) and the steering head angle remains at 62.9° (27.1° caster) in standard position.

A change in front wheel kinematics eliminates brake dive to an insignificant residual effect actually designed to give the rider the right feeling.

The superior stiffness of the Telelever, in turn, has been further enhanced by once again increasing the diameter of the support tube from 35 mm (1.38″) to 41 mm (1.61″), thus making a further contribution to the crisp and clear riding behavior of the R 1200 GS.

An important detail is the holes drilled into the lower fork bridge efficiently distributing brake pressure to the steel flex brake hoses for the right and left brake calipers without requiring an additional distributor unit.

Featuring fully encapsulated ball joints with permanent lubrication and with a lifetime oil fill in the telescope, the entire Telelever is absolutely maintenance-free.

Revised Suspension

To optimize riding qualities off the beaten track, the spring base of the front gas pressure spring strut is mechanically adjustable to 9 different position in order to provide extra reserves even under the toughest off-road conditions.

Spring travel at the front is 190 mm (7.48″), with a 68 mm to 122 mm ((2.68″ to 4.80″) ratio in the basic setting between the outward and rebound mode.

Real-wheel suspension incorporates a high-tech gas pressure spring strut with travel-dependent damping (TDD) and infinite hydraulic adjustment of the spring base by means of a hand-wheel.

The damping effect in the outward mode is manually adjustable. The travel-dependent damping principle was introduced by BMW Motorrad for the first time in 2002 on the R 1150 GS Adventure, providing a progressive damping effect as a function of spring travel.

The machine therefore responds smoothly and comfortably to even the smallest bumps on the road, while nevertheless offering adequate potential for rough terrain with hard jolts and deep holes in the surface.

Spring travel at the rear is 200 mm or 7.87″, with positive (inward stroke) versus negative (rebound) spring travel being increased over the former model to a new ratio of 135 mm to 65 mm (5.31″ to 2.56″) in the basic setting.

Wheels and Tires

Offering a choice of cast or cross-spoke wheels for the first time, the lucky purchaser of the new R 1200 GS has the choice of either high-strength cast light-alloy wheels or BMW’s well-known cross-spoke wheels.

They measure 2.50 x 19 ” at the front and 4.00 x 17″ at the rear and running on 110/80 -19″ front and 150/70-17″ rear tires.

New Wheel Design

Developed for the R 1200 GS, the cast light-alloy wheels with five double spokes are both stable and light.

And while at 0.1 kg, the reduction in weight at the front versus the spoke wheel is virtually negligible, weight reduction at the rear is a significant 1.6 kg, down by 12 percent.

A big advantage of cast wheels is that they retain their excellent running smoothness and circular geometry throughout a long running life and are easier to clean.

Clearly, this makes them first choice for riding on roads and un-tarred tracks.

Benefiting from their special design and configuration, the cast wheels on the R 1200 GS are likewise fully suited for moderate off-road conditions.

Gravel tracks, nature trails and the usual off -road tracks to be found all over the world are no problem with these wheels as long as the “normal” rider maintains a moderate style of riding observing the elementary rules.

In practice, therefore, cast wheels reach their limit only when exposed to very substantial loads over a long period, for example on extreme tracks, at high off-road speed, and when jumping on rough terrain with violent bumps and jolts.

The ambitious off-road rider using his R 1200 GS mainly off the beaten track and often mastering rough terrain at high speeds, should therefore opt for BMW’s proven cross-spoke wheels.

They are naturally also a good alternative for the rider not keen on cast wheels on his enduro. As before, the particular arrangement of the cross spokes also allows the use of tubeless tires and the spokes can be replaced individually.

Brakes: High-Performance EVO Brakes and Integral ABS

The R 1200 GS is fitted with BMW’s well-known EVO brake system, which has already proven its benefits such as maximum stopping power under minimum manual force on the R 1150 GS and other BMW machines.

Brake disc diameter is 305 mm or 12.00″ at the front and 265 mm or 10.43″ at the rear.

As an option at extra cost, the R 1200 GS is also available with BMW Integral ABS already well-known on the former model.

Complete with on-demand deactivation when riding off-road, Integral ABS also features a semi-integral function with the handbrake lever activating both brakes on the front and rear wheel.

In the conventional mode, by contrast, the footbrake lever acts only on the rear wheel brake for precise application of the rear brake alone under specific conditions in very tight bends and on rough terrain.

The stainless-steel-clad brake lines, finally, not only look good but also offer a slight decrease in weight and ensure an even more stable pressure point.

BMW Motorcycle Single-Wire System (SWS)

Yet another special feature of the R 1200 GS is the all-new on-board electric system.

The term Single-Wire System describes a highly innovative on-board network using electronics and CAN-bus technology (Controller Area Network) to offer functions and features never seen before.

Reducing the number and length of cables required, this network offers a much wider range of functions than a conventional on-board network, information being transmitted along just one single path (hence “single-wire”) as opposed to the double-wire system otherwise required.

Apart from the wide range of functions, the main advantages of this intelligent combination of electric and electronics are the lighter wiring harness, substantial resistance to interference, and the complete range of diagnostic functions.

A further point is that the system may be flexibly expanded by simple updates.

The basic principle of the single-wire system is to connect all control units, sensors, and power-consuming items via one single, common wire.

This will form a complete network transmitting all signals regardless of their subsequent function. In other words, all information is readily available at all times within this network for all the components attached.

Signals are assigned and transmitted to the respective power-consuming item at junction points in the electronic system of each control unit. Here the signals/data are processed and then used to activate the functions desired in the respective power consumer.

This eliminates the need for elaborate cables otherwise required for each function operating through a separate wire, thus reducing potential effects and errors in a conventional on-board network otherwise resulting from the large number of cables.

Clearly, this is an important factor contributing to the system’s high standard of reliability. All control units are connected to one another, thus being able to communicate directly and exchange data in a bi-directional mode.

This allows simple and comprehensive diagnosis of the overall system from one central point, the electronics incorporating suitable programs in order to filter out unimportant data and interference signals within a defined tolerance.

It makes the system less sensitive to electromagnetic disturbance.

Control Units

The new R 1200 GS comes in standard trim with three control units (the cluster instrument also representing a control unit of its own).

The control unit for the Digital Motor Electronics (BMS-K) is not only responsible for the engine management already described, but also transmits all data to the central diagnostic system.

Central Suspension Electronics (CSE), in turn, serves to mastermind the electrical units and functions not specific to the engine.

And if the motorcycle is fitted with Integral ABS and an anti-theft warning system as an option, the control units are also integrated in the network.

There is no need for conventional fuses at any point throughout the on-board network, the electronic “brain” simply switching off the function involved in the event of a short-circuit or malfunction, subsequent diagnosis serving to quickly trace and remedy the defect.

And since the other functions are not affected in such a case, the network philosophy featured on the R 1200 GS again offers further advantages in terms of reliability and failsafe operation.

The control units also provide relay functions, only the starter being controlled via a conventional relay.

Electrical System

The electrical system on the R 1200 GS is supplied with power by a low-weight alternator developing 600 Watts at 40 Amps.

The maintenance-free battery has a capacity of 14 Ah.

After 20 years of experience in electronic engine management and 15 years of experience with ABS technology, BMW Motorrad, introducing this new on-board network, has taken its next innovative step into a successful future.

Electronic Immobilizer

To ensure optimum security at all times, the R 1200 GS comes with an electronic immobilizer standard.

Controlled by a transponder in the key, the immobilizer offers the very best in anti -theft security, maintaining the same high level to be found in BMW cars.

As soon as the rider inserts the key and switches on the ignition, a chip within the key communicates with the electronic immobilizer integrated in the Digital Motor Electronics via the ring aerial integrated in the ignition lock.

This allows the systems to exchange and compare the coded chip data, on the one hand, and the electronic immobilizer data, on the other.

After confirming that the data and signals comply with one another, the engine control unit will release the ignition and fuel injection, allowing the rider to start the engine. This technology is the best and safest immobilizer system currently available worldwide.

New Instrument Cluster

The new on-board electronic system featured on the R 1200 GS allows the introduction of a high-tech, extra-light instrument cluster based completely on digital technology.

It incorporates the speedometer, tachometer and the Info Flat-screen Display.

The instrument cluster replaces the former Rider Information Display, providing permanent information on the oil temperature, fuel level, remaining range on the fuel in the tank, the time of day, and the gear currently in mesh.

Both overall and trip mileage are presented on demand, and any interference or defects are shown on the screen as a printed message.

The entire instrument unit is automatically illuminated as soon as the weather gets dark, with precise control by a photoelectric cell.

Electric Switches

Both the switches and controls are new. While the basic arrangement of the switches and BMW’s logic for operating the direction indicators have both BMW been retained, the switches are now even easier to use and reach.

And they come in even clearer, more distinctive design.

Body and Design

Numerous motorcycle components form a close link of function and looks at the outside, much more so than on a car.

The fuel tank, for example, is not just a container for fuel, but also a highly significant design feature crucial through its shape to the rider’s seating position and the overall look of the motorcycle.

The same applies to the front fairing together with the windshield not only protecting the rider, but also – in conjunction with the headlight – giving the entire motorcycle its special “face” and characterizing the look of the machine also in the front side area.

Using BMW motorcycle language, the faring components, the fuel tank as well as other function and control elements are jointly referred to as the “body” of the motorcycle.

In its overall design and look, the R 1200 GS stands for dynamism, agility and lightness combined with the robustness typical of an off-roader.

Clearly structured and contoured surfaces create a feeling of tension and excitement, interacting to provide clear and harmonious lines.

Various surfaces finished in plastic, paint and aluminum are assigned to specific functions, combining elegance and value with the ruggedness rightly expected of an enduro.

All visible technical components are included in the design of the machine, the delicate structure and light character of the rear sub-frame being enhanced and accentuated by the silver paintwork.

The slightly curved, oval form of the Paralever swinging arm, finally, combines superior stiffness with a slender and dynamic look all in one.

Color Scheme

The color scheme (see below) offers a perfect blend of diversity and aesthetic style, setting unique accents in the process.

And with the owner being able to freely combine the color of the paintwork with that of the seat and side covers, the connoisseur obviously has a wide range of choice.

The three basic colors are elegant and classic; Ocean Blue metallic and two special Rock Red and Desert Yellow non-metallic color schemes both highlighting the sporting character of the R 1200 GS.

Two seat colors (Light Grey and Black) as well as two different colors on the tank side cover (Granite Grey and Black, soft paint) provide a total of 12 different combinations, each giving the motorcycle its own particular character.

Front Fairing With Adjustable Windshield

Through the functions they comprise, the components on a motorcycle also vary in design.

Seen from the front, the fairing, for example, is a typical, striking and distinctive sign of character giving the GS its particular identity. And at the same time this component serves as the air guide for the oil cooler.

The new BMW R 1200 GS provides a modern rendition of the design features already boasted by the former model around the headlight.

Indeed, the all-new, asymmetric dual headlight unit with the low and high beams varying in diameter gives the GS its characteristic “face”.

At the same time the reflectors in free -form technology as well as the clear glass cover make it quite obvious from the start that the entire headlight unit is brand-new.

The oval design of the reflectors is indeed not only up-to-date, but also enhances illumination of the road ahead thanks to the large light outlets.

The windshield adjusts to five different angles without requiring any tools in the process, offering riders of different size optimum protection from wind and weather through its design alone.

The two plastic side covers right and left at the side of the tank, in turn, come off easily by means of rapid catches.

Plastic Fuel Tank With Side Covers

The 20-liter fuel tank on the R 1200 GS is made of special, extra-light and impact-proof plastic.

Two side covers made of thin aluminum and a painted top cover give the tank its special shape and look.

Appropriately slender towards the rear, the tank offers good knee and leg support also when riding off-road whenever the rider is standing upright on the footrests.

Seat

The seat has an ergonomic design and greater variability of seat height. Maintaining BMW’s usual standard, the new two-piece double seat offers both the rider and passenger ample space.

The seat is not only available in two colors, Grey and Black, but it also adjusts to two different height levels for the rider (840 mm and, respectively, 860 mm/33.1″ and, respectively, 33.8″).

And a higher (+30 mm/1.18″) and lower (-30 mm) seat also being available as special equipment.

Thus, the customer is able to choose among four different height levels ranging from 810 mm (31.9″) to 890 mm (35.0″), thus benefiting from unprecedented variability and freedom of choice.

In determining the ideal seat height and contour on the R 1200 GS, BMW’s engineers and designers have applied a new dimensional criterion for the first time: the rider’s step length.

Forming the entire distance between two resting points of the rider’s feet (measured across the inner length of the legs), this criterion considers not only the absolute, geometric height of the rider’s seat, but also its shape and width throughout the relevant area at the front.

Even where geometric seat height is the same as on the former model (840 mm/33.1″ and, respectively 860 mm/33.8″), this new seat design significantly improves the rider’s ground contact while keeping the knee bending angle when riding within comfortable limits.

Luggage Rack and Removable Passenger Seat

Made of stable but light plastic, the luggage rack on the R 1200 GS is all-new in design and offers adequate storage space for additional luggage easy to fasten and transport safely thanks to the lashing points.

A further option is to fit a top case, and the plastic cover beneath the removable passenger seat serving as a flat loading area at the same level as the top edges of the case is both functional and practical all in one.

Fitting the cases available as special equipment here, the rider has lots of space for additional baggage, once again with integrated lashing points for optimum security.

Ergonomic Handlebar Design

Made of thin-walled steel tubes, the strong and stylish handlebar easily copes with the heaviest loads and is tapered at each end.

Weighing only slightly more than an aluminum handlebar, a steel handlebar is much less prone to damage should the machine fall over to the side (for example on off-road terrain) and allows emergency repairs.

A further advantage of the steel handlebar is the lower thermal conductivity of steel retaining the heat where it belongs when the machine is fitted with heated handles available as an option.

The hand levers for operating the clutch and brakes have been optimized for perfect ergonomics and are adjustable in their span.

At the same time the diameter of the handles h as been reduced to provide an even better grip.

(top)

Optional Extras and Special Equipment

Cases are variable in size and have a wide range of customization features.

A complete systems supplier by tradition, BMW Motorrad has developed a wide range of customized extras and special equipment for the new R 1200 GS, offering the owner the very best in individual choice.

Optional extras are fitted directly at the factory in the production process in Berlin. Special equipment, in turn, is fitted by the BMW motorcycle dealer.

Optional Extras

- BMW Motorcycle Integral ABS (semi-integral and with on -demand deactivation).

- Cross-spoke wheels.

- Heated handles.

- Hand protectors.

- Case supports.

- Anti-theft warning system.

Special Equipment

- High rider’s seat (+30 mm/1.18″ versus standard seat), adjustable (max seat height 890 mm/35.0″).

- Low rider’s seat (–30 mm/1.18´ versus standard seat), adjustable (lowest seat height 810 mm/31.9″).

- Case supports.

- Cases variable in size by single-lever control.

- Mounting plate for topcase.

- Topcase

- Inner bags for cases/topcase.

- Water-tight tank bag.

- Hand protectors.

- Small cylinder protection hoops.

- Large cylinder protection hoops.

- Anti-theft warning system (also available as an optional extra).

- Additional power socket.

- BMW Motorcycle Navigator.

Luggage Notes

Both the cases and the top case are an all-new development. A unique feature is the sophisticated, single -lever control function for adjusting the volume of the cases easily and conveniently.

Both the cases and the top case may be varied in size by 9 liters, allowing the rider to flexibly adjust the luggage system to individual space requirements and reduce the width of the cases as well as the height of the top case when taking along less luggage.

The left-hand case on the muffler side offers maximum capacity of 37.5 liters, the right-hand case holds up to 46 liters.

With the top case also offering capacity of 46 liters, maximum storage capacity is almost 130 liters.

(top)

BMW R1200GS Horsepower and Torque Curves

BMW R1200GS Specifications (top)

BMW R1200 GS Available Colors (top)

Master Listing of All wBW Motorcycle Product Reviews

Owner Comments and Feedback

See details on submitting comments.

Balance Shaft

Balance Shaft

No Comment